In recent years,efficient logistics management and theimplementation of automated warehouses have radically transformed the landscape of global marketplace sales.

This change has not only optimized the processes of product sourcing, warehousing, and shipping, but also opened new frontiers insupply chain optimization, enabling greater speed, accuracy, and reliability in business transactions on a global scale.

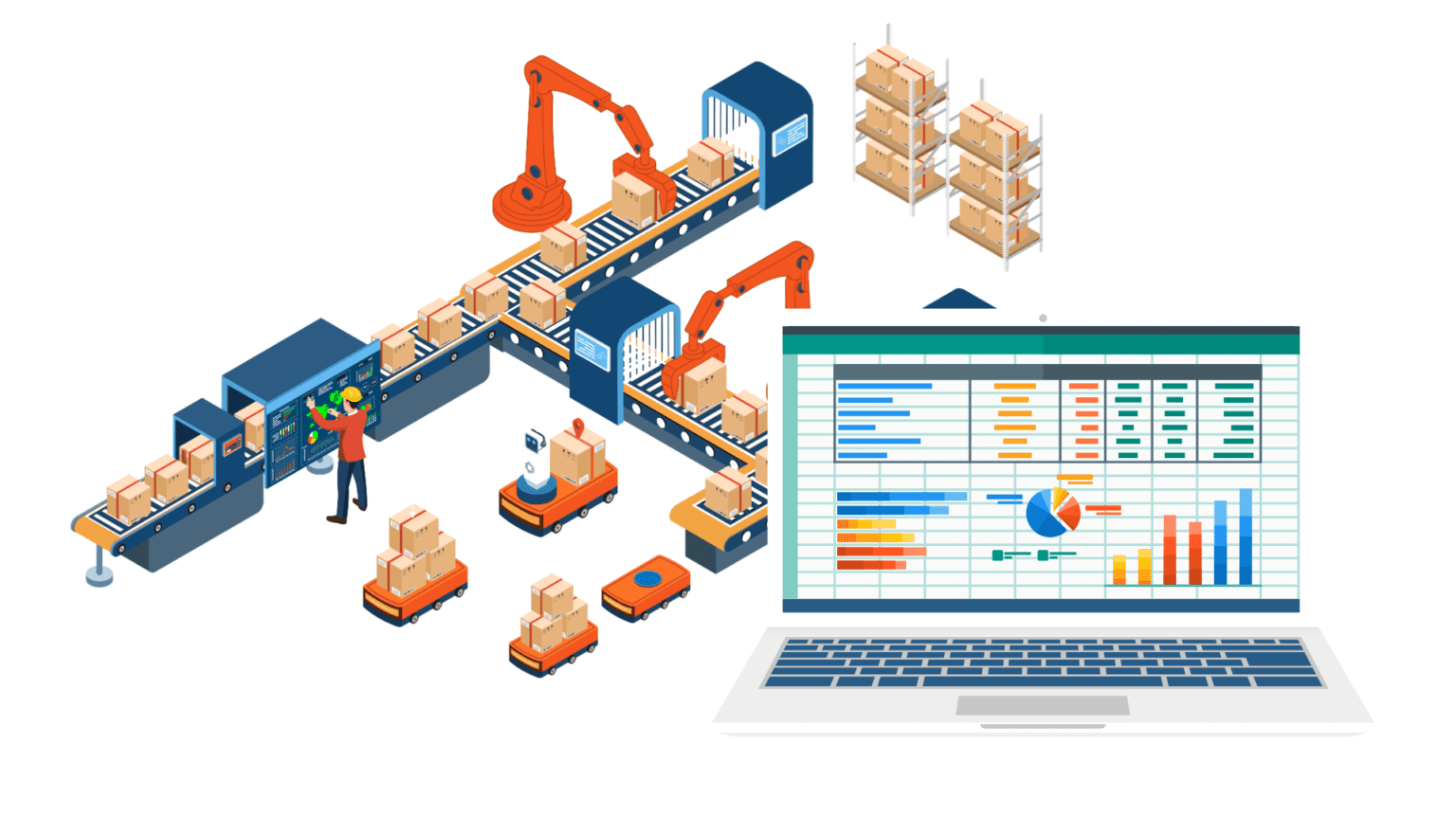

Automated Logistics

Automated logistics, with the use of robots and autonomous systems, is radically transforming the supply and shipping chain. From autonomous robots in warehouses to automated picking solutions,operational efficiency is reaching new levels.

This not only reduces errors and speeds up delivery times but also allows for more flexible demand management.

In particular, the implementation of advanced robotics enables faster and more precise handling of materials within warehouses, optimizing space and improving overall productivity.

Autonomous systems, because of their learning capability, can adapt quickly to changes in demand and environmental conditions, ensuring a more resilient and responsive supply chain.

Robotized Vertical Warehouses

The adoption of robotic vertical warehouses enables smarter use of available space.

These warehouses take advantage of height, allowing greater storage capacity without increasing physical area. Autonomous robots handle product picking and placement, further improving efficiency and reducing wasted space.

The use of advanced monitoring and control technologies enables optimized inventory management, allowing companies to track the flow of goods within warehouses in real time and more accurately forecast replenishment needs.

In addition to this, robotic vertical warehouses also contribute to greater environmental sustainability, as they reduce the need to expand physical infrastructure and can be designed to optimize energy efficiency and reduce carbon emissions.

Advanced logistics and automated warehouses: the partnership between Yocabé and Asendia

Technological innovation and advanced logistics are thus defining a new era for e-commerce, an unprecedented revolution in which our new partnership with Asendia fits.

Asendia is now a key player in theglobal logistics evolution, offering innovative solutions that can redefine the rules of the game in the field of international shipping.

The combination of advanced logistics, automated warehouses and a strategic vision positions Asendia as the right partner to make a difference in the complex world of global shipping.

Yocabé seized this opportunity with a partnership that enabled a number of advantages in developing the performance of managed brands while contributing to their success.

Benefits of partnership

#1 Certain Processing Times

Warehouse automation is the key to ensuring certain and timely processing times.

Rigid lead times are crucial to excel in global marketplaces, maintain impeccable standards in shipping time management, and achieve a high-quality customer experience while enhancing brand reputation.

#2 Competitive Shipping Costs

With a view to internationalization, the strategic use of local couriers and a focused vision have resulted in competitive shipping costs, regardless of the destination.

Selling products localized in Italy as if they were already in the target country has opened up new prospects for Yocabé brands.

This strategy has not only reduced shipping costs, but also expanded the brands’ reach, providing a global customer experience.

#3 Improvement of Expected Customer Benefits

This approach has not only improved operational efficiency and reduced costs, but has also generated tangible benefits for customers.

Being able to offer the same benefits as local shipping, such asno duties in certain destinations, has helped create a lasting bond between brands and their customers.4

Thus, we can say that the combination of well-developed global logistics, the adoption of automated warehouses, and the implementation of innovative strategies have provided opportunities for different brands to thrive and grow on an international scale.

In addition, warehouse automation has not only streamlined the storage and handling of goods, but has also enabled companies to focus human resources on high-value-added tasks, such asdata analysis and the development of more targeted marketing strategies, thus helping to consolidate their presence in the international market.

Conclusions

Thus, we can say that the combination of well-developed global logistics, the adoption of automated warehouses, and the implementation of innovative strategies have provided opportunities for different brands to thrive and grow on an international scale.

Advances in logistics and supply management enable companies to reach otherwise inaccessible markets and adapt to changing consumer needs more quickly and efficiently.